Inconel wire is a nickel and chromium alloy wire offering excellent corrosion resistance suitable for operation in high temperatures. We supply nickel based alloy spring wire rolls, with sample qualification approval before bulk supply.

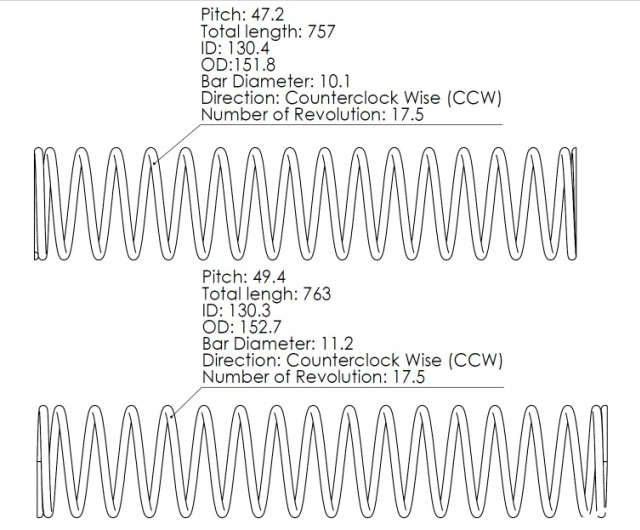

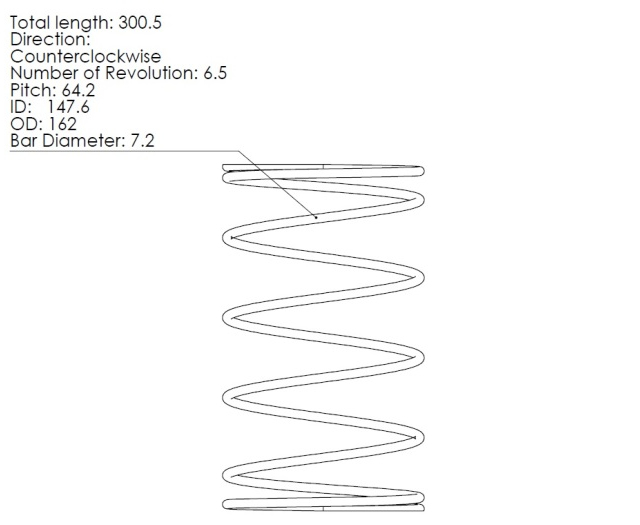

Pupular sizes: Spring wire 4mm, 5mm, 7.2mm, etc.

Inconel 600 Spring Wire

Inconel 600 spring wire is quality cold drawn wire made from a nickel base. It provides good corrosion resistance at operating temperatures up to 900°F.

Inconel 718 Spring Wire - Inconel 718 Nickel Alloy

For safty valve spring

GH-4169 Inconel Spring Wire

Wire diameter: 4.0 ± 0.04mm

Material Name: Inconel Spring Wire

Material Grade: GH4169

Product Condition: Solution Treated & Cold-Drawn

Manufacturing Conditions:

The ingots for fabricating the GH4169 alloy wires shall be melted by using vacuum induction and electroslag re-melted process.

The wires shall be performed solution treatment and then be cold-drawn, finally be delivered at the cold-drawn condition.

The recommended solution treatment is: maintaining at (950-1040)℃ for (0.5-1) hour, then water cooling.

The wires should be of coil shape and it should be in good order in the coil. The wires shall not become loose, twisted or ∞ shape while opening the wire coil.

There should be no scabs and weld joints.

Inconel Metal Chemical Composition (wt %):

| Element | C | Mn | Si | Cr | Ni | S |

| Content | ≤0.08 | ≤0.35 | ≤0.35 | 17.0-21.0 | 50.0-55.0 | ≤0.015 |

| Element | P | Ti | Al | Nb | Mo | Co |

| Content | ≤0.015 | 0.65-1.15 | 0.20-0.80 | 4.75-5.50 | 2.8-3.3 | ≤0.10 |

| Element | Ta | Cu | B | Fe | ||

| Content | ≤0.10 | ≤0.10 | ≤0.002 | Rest | ||

Metallography:

Grain Size ≥grade 6

Non-Metallic inclusions ≤grade 6

Mechanical Properties:

Mechanical properties of wires shall meet the following requirements:

| Wire Diameter (mm) |

Tensile Strength Rm, MPa |

Elongation (%) A11.3 |

Reverse Bending (times) |

Unilateral Torsion (times) |

|

| Al Room Temperature |

At 350°C | At Room Temperature |

At Room Temperature |

At Room Temperature |

|

| Cold- Drawing + Ageing |

Cold- Drawing + Ageing |

Cold- Drawing + Ageing |

Cold- Drawing |

Cold- Drawing + Ageing |

|

| <5.00 | 1520-1700 | ≥1370 | ≥4 | ≥4 | ≥5 |

| ≥5.00 | 1470-1650 | ≥1325 | ≥4 | ≥3 | ≥4 |

Non-Destructive Testing:

The surface of wires shall be smooth and clean. There shall be free of defects such as cracks, hair folds, layers, spilliness, drawn marks, scars, grooves and pocks etc. on the surfaces. It's permitted for the existence of individual drawn marks and grooves with the depth not exceeding 0.03mm.

The surface roughness (Ra) of wires shall be equal to or less than 3.2μm.

Certifications:

All the requisite testing / processing certification to ensure that the material meets specification, but not less than mentioned certifications:

• Melting Method

• Heat Treatment Process

• Chemical Composition

• Dimensional Inspection

• Mechanical Property

• Metallographic Examination

• Surface Quality Inspection

• Results of Retest (if any)

Re-Examination:

In sampling tests, if the results of the specimens fail to meet the requirements for any item, double specimens shall be taken and retested for that item.

Lot will be rejected in case re-examination is not qualified.

Packaging & Delivery Conditions:

Packing: 5Kg per Roll

The packaging and marking of the wire shall meet the requirements described in ASTM A 700 / GB 2106 (Class-11).

Each bundle or shipping containers indicate:

Contract Number, Name of Material, Condition, Size, Lot Number, Net & Gross Weight, Quantity & Supplier Identification

Applicable Standards:

GB/T 222, GB/T 2103, GB/T 223, GB/T 2976, GBAT 228.1, GB/T 4338, GB/T 238,

GB/T 6394, GB/T 239, GB/T 14999.5, ASTM A 700 / GB 2106, GB/ T 20066